ASBTDC client CelluDot recently won a National Science Foundation Small Business Technology Transfer grant to demonstrate feasibility of its patent-pending biopolymer technology, BioGrip™, for reducing herbicide drift.

Herbicide drift, the off-target movement of agrochemicals to unintended places, is a growing problem in agriculture.

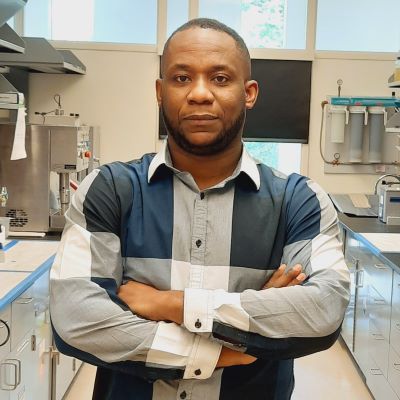

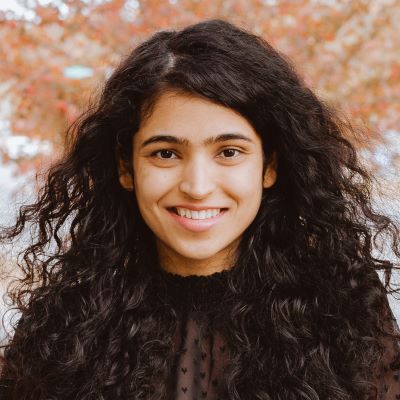

The CelluDot Project Team

CEO Joseph Batta-Mpouma and CTO Dr. Gurshagan Kandhola are co-inventors of the technology.

Batta-Mpouma is a Ph.D. candidate in materials science and engineering at the University of Arkansas at Fayetteville and has certifications in entrepreneurship and business management from the university’s Sam M. Walton College of Business.

Kandhola is a post-doctoral fellow in UA’s Biological and Agricultural Engineering department and the Division of Agriculture. She has expertise in technology innovation consulting as well as a certificate in entrepreneurship from the Walton College.

Both Batta-Mpouma and Kandhola have experience working with cellulose materials through an NSF EPSCoR grant by the Center for Advanced Surface Engineering.

CelluDot has amplified the strength of its team with an experienced board of advisors.

ASBTDC Assistance

The Arkansas Small Business and Technology Development Center supported the company’s pursuit of STTR funding.

“ASBTDC has been a huge resource for CelluDot right from the beginning. Their staff assisted us with market research, which helped us identify some key industry trends in the agrochemical space. In 2020, we participated in the NSF cohort of their Lab2Launch accelerator program, which was extremely valuable in learning the details of the SBIR/STTR application process and simply keeping us on track,” said Batta-Mpouma.

“Rebecca Todd was our main point of contact for all engagements with ASBTDC, and we are grateful for all her help and support throughout our journey. She also helped us with a Technology Transfer Assistance Grant, through which CelluDot was able to engage with an independent consultant to prepare our proposal. Huge kudos and thanks to both Rebecca and Eileen Devereux for participating in every single call, answering all sorts of questions, and reviewing and providing valuable feedback on our proposal,” said Kandhola.

Market Need

Over the past few years, farmers, particularly those growing non-genetically modified soybeans and cotton, have suffered crop damage and financial losses due to dicamba drift.

Per EPA estimates, 70 million pounds of pesticides are lost to the environment each year in the U.S. In 2017 alone, 3.6 million acres of soybeans were destroyed due to dicamba drifting from its site of application. Beyond crop damage, herbicide drift is harmful to human health and pollutes the environment.

As part of the New Venture Development course co-taught by Dr. Carol Reeves and Sarah Goforth at the Walton College and to assess the market potential of the technology, CelluDot participated in the University of Arkansas’ NSF I-Corps Site program from May-June 2019 and the Arkansas Delta I-Fund accelerator program from August-November 2019 as well as ASBTDC’s Lab2Launch accelerator from March-June 2020.

“Through these programs, CelluDot identified key stakeholders in the industry and conducted over 100 interviews with farmers, crop consultants, weed scientists, extension agents, farmer co-ops and agrochemical companies,” said Batta-Mpouma. “Nine out of ten farmers stated that current drift-control additives are ineffective in reducing drift of volatile herbicides such as dicamba and that vapor drift is the red-hot pain point that urgently needs a solution. That insight validated the market need for CelluDot’s core technology.”

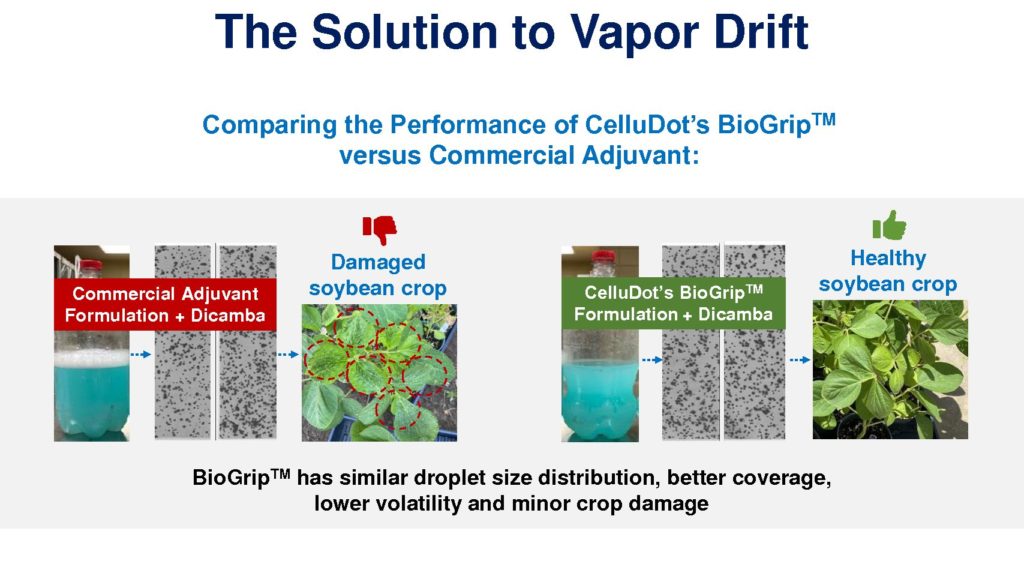

CelluDot’s Solution: BioGrip

“We seek to reduce the vapor drift of volatile herbicides like dicamba using our patent-pending biopolymer technology. Our solution is a formulation consisting of nanocellulose-based networks that bind to the herbicide, reducing its vaporization and increasing its adherence to plants. By combining the functionality of various ingredients in a single formulation, our convenient one-step solution will reduce farmers’ risk of errors during the preparation of their tank mix, while keeping the overall cost comparable to that of existing herbicidal additives,” said Kandhola.

In the NSF STTR Phase I project, CelluDot has four key objectives:

- Develop the composition of its BioGrip formulation;

- Characterize properties important for its commercial application;

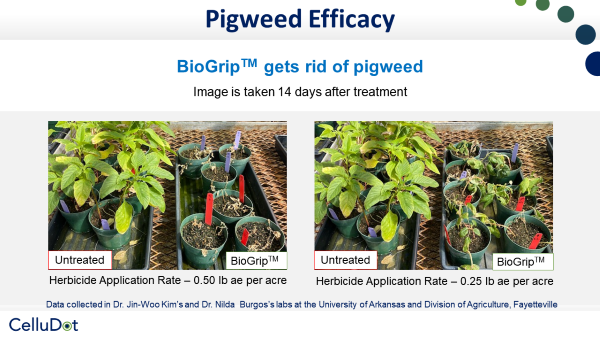

- Validate the effectiveness of BioGrip with respect to vapor and particle drift reduction and herbicidal activity against pigweed; and

- Validate the biodegradability and safety of BioGrip in soil and water environments.

“The Environmental Protection Agency and state agricultural plant boards and agencies have increased restrictions on dicamba usage to curb the recurring problem of drift. The primary challenge for CelluDot will be to evaluate the regulation risk. EPA’s recent approval of five-year registrations of previously banned dicamba products is good news for CelluDot because it is now required that additives that control its volatility are added to the tank mix. We are confident that CelluDot will serve this market need with its novel technology in the near future, bringing much-needed relief to farmers. CelluDot also plans to engage with a regulatory consultant to ensure appropriate study protocols are followed to obtain their approvals and labels,” shared Batta-Mpouma.

What’s Next for CelluDot?

“The community can help us promote the product through their own channels such as farmers co-ops, which farmers heavily rely on for their farming needs and supplies. Above all, when proven successful at the research level, we would love to gain access to farmers who are willing to test out our product on small portions of their farmland,” said Kandhola.

CelluDot will continue to pursue non-dilutive funding through additional SBIR/STTR grants with agencies such as the EPA and U.S. Department of Agriculture, as well as matching grants available in Arkansas.

“We will also partner with the Division of Agriculture for pilot testing at the Arkansas Agricultural Experiment Station and begin to engage with agro-chemical companies that manufacture and distribute herbicides and adjuvants to farmers,” affirmed Batta-Mpouma.