Fayetteville-based Ozark Integrated Circuits has received a $750,000 NASA Small Business Innovation Research Phase II award to develop sensing and actuation solutions that can survive in the high-temperature, high-pressure environment found on Venus.

In addition, Ozark IC won a $205,000 Department of Energy SBIR Phase I award to create ruggedized communication technology for enabling high-temperature directional drilling. “The geothermal exploration environment is surprisingly very similar to the conditions on the Venus surface in terms of temperature, pressure and corrosive atmosphere,” said Dr. Matt Francis, CEO of Ozark IC.

NASA SBIR Phase II Project

In the Phase I project, Ozark IC worked with Honeybee Robotics to develop an architecture for the high-temperature electronics required to drive the motor at the Venus surface under its corrosive atmosphere and temperature. “This Phase II project naturally follows the approach and results obtained from the very successful Phase I project. Our partner, Honeybee Robotics, has developed a high temperature motor that will work at Venus surface temperatures that are nearly 500⁰C – the highest planetary surface temperature in our solar system,” said Francis.

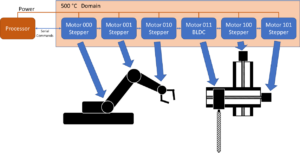

“The Phase II project will expand the electronic system to include control of the motor using a single state machine architecture. Using this architecture, up to eight motors can be controlled on a single bus,” said Jim Holmes, Chief Technology Officer for Ozark IC. Below is an illustration of an actuator system.

“This project will combine Honeybee Robotics’ DC motors with the special silicon carbide technology developed by the NASA Glenn Research Center. Our high-temperature process design kit for this technology will be used to design an integrated stepper motor driver that can be serially controlled. Proof of concept will be demonstrated through prototyping, using Ozark IC circuits that were fabricated by NASA Glenn. System performance will then be estimated through high-fidelity simulation,” said Holmes.

DOE SBIR Ph I Project

“In this Phase I project, we will apply our high-TRL Silicon on Insulator integrated circuitry and packaging technologies, currently being used for turbine engine control applications, to enhance state-of-the-art drilling systems. The system will operate for extended times at 250oC. This will be accomplished by effectively designing a high-temperature communication system,” said Francis. Ozark IC is partnering with Cole Engineering (also located in the Fayetteville Research Center building) on this system design.

Meeting the Customer Need

NASA

“NASA has demonstrated a resolve for a flagship mission in the coming years to revisit Venus and land instruments on the surface. Venus has a corrosive, high-pressure (~100 bar), high-temperature environment. Previous missions to Venus lasted no more than two hours in the Venus atmosphere. In Phase I, we were able to demonstrate 38 days of operation in these conditions!” said Francis.

A motor drive is the major theme that runs through the most critical needs for optimum geological and atmospheric exploration on Venus.

“An electronically controlled motor, operating at 470°C per 100 bar, is the single most significant demonstration of the ability to perform robotic Venus surface exploration and the ultimate objective of the project,” said Holmes.

Geothermal Exploration

“Technology that provides improved exploitation of subsurface resources presents a tremendous opportunity to improve our world. Geothermal resources, in particular, could provide gigawatts of carbon-free base load, with obvious economic and societal benefits,” said Dr. Ian Getreu, Ozark IC’s director of business development and strategic partnership.

A high-temperature drilling telemetry system provides a clear capability for accessing subsurface resources. “The first application of this technology to improve high-temperature drilling using silicon on insulator technology can quickly enable access to a tremendous amount of enhanced geothermal systems resources at temperatures up to 250oC. When combined with other silicon carbide technologies already under development by Ozark IC, access to deeper resources will become possible,” said Francis.

Engaging Potential Customers

Ozark IC has spent several years working with potential customers in three basic high-temperature markets:

- space exploration – NASA

- geothermal exploration – DOE and two commercial companies

- jet engines – the U.S. Air Force and the Distributed Engine Control Working Group, which contains most of the top jet engine manufacturers and their suppliers

“Jet engine manufacturers are eager for high-temperature electronics and actuation to increase reliability and to save weight and fuel,” said Getreu.

“Our approach with customers is to listen very carefully to their needs. There is a bit of ‘chicken and egg’ in this process. Customers need to be convinced that talking to us is worth their while. We need to have done our homework: understand the market and its needs and what we can do to help. And this is where Rebecca Todd and market research staff at the ASBTDC come in – they have been of tremendous help in researching market sizes and primary contacts at each organization. We could not have established our relationships or been successful with our proposals without their help,” said Getreu.

Ozark IC Expertise

Ozark IC and its partners have established trade secret production procedures over the last several years. These procedures have produced proven high-temperature circuits, platforms and packages.

“The next year will illustrate our production procedures in operation. We have hired two production experts, Dr. Silke Spiesshoefer and Jacob Kupernick, who will be running our production lines,” said Francis.

ASBTDC Assistance

“ASBTDC’s marketing analysis and customer awareness services have been crucial to Ozark IC’s success in SBIR/STTR proposals. Reviewers have commented on the reasonable numbers provided and the key personnel in several companies have provided very-well-received letters of support,” said Getreu.

Advice for Prospective SBIR Applicants

Francis had three pieces of advices for Arkansas-based SBIR applicants:

- Work with ASBTDC – use all their services and advice

- Understand your markets and needs

- Don’t exaggerate – tell it like it is