SIEV Technologies of Fayetteville has won National Science Foundation funding for a technology that turns biomass left over from the ethanol manufacturing process into material for making more ethanol.

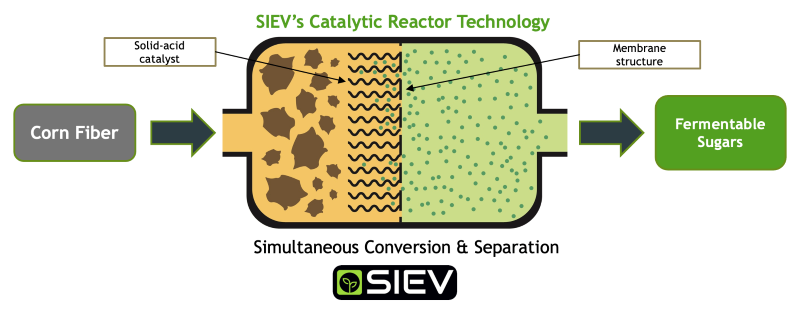

With the NSF Small Business Innovation Research Phase I award of $256,000, SIEV will demonstrate that the company’s novel catalytic membrane technology can be fine-tuned to take corn fiber, a byproduct of the corn-to-ethanol process, and convert it into sugars suitable for ethanol production.

The technology is designed as a “bolt-on” system that ethanol producers can easily integrate into their existing process without having to construct new facilities.

In the U.S., 386 million tons of biomass waste are generated annually. SIEV wants to reduce waste, increase manufacturing efficiency, and create value-added, sustainable products all at once.

“Our aim is not to exclusively target and stay in the ethanol/biofuel industry,” said Davar Sasongko, company co-founder and CEO. “As we begin NSF SBIR Phase I activities, we will continue to research other potential feedstocks and the market potential of the platform chemicals we can create. This will enable us to prepare other SBIR/STTR proposals as we push towards our long-term goals and a more sustainable future.”

Along with Sasongko, SIEV is led by two other co-founders, chief technology officer Ranil Wickramasinghe and chief scientific officer Xianghong Qian.

All three are part of the College of Engineering at the University of Arkansas at Fayetteville. Dr. Wickramasinghe is the Ross E. Martin Chair in Emerging Technologies in the Department of Chemical Engineering and heads the Membrane Science, Engineering and Technology (MAST) Center. Dr. Qian is a professor in the Department of Biomedical Engineering. Sasongko is a senior research assistant.

Zhexi Zhu, PhD candidate/researcher, Biomedical Engineering (photo courtesy of SIEV)

ASBTDC Support Helps SIEV Succeed on 1st Attempt

Sasongko worked closely with the Arkansas Small Business and Technology Development Center on the NSF proposal. ASBTDC innovation consultants “were invaluable throughout the whole SBIR application process,” he said.

“(They) helped with proposal planning, feedback, and review, which eventually led to a successful application. They also helped with obtaining market research reports for our team to study and reference, and even assisted us in obtaining other funding in the form of a TTAG, a Technology Transfer Assistance Grant, to submit the SBIR application.”

The company connected with Rebecca Todd, ASBTDC innovation specialist, in October 2020 and completed the proposal in two months.

“We had an aggressive deadline that we needed to meet, and it was the first SBIR application we prepared. Rebecca helped set up the deadlines, advised us on the application process, and provided us valuable feedback on the proposal. Rebecca was great at answering our questions, and she always got back to us promptly,” Sasongko said.

After I-Corps, Team Zeros in on Ethanol Market

Taking part in an NSF I-Corps cohort in 2020 led the company to decide ethanol was the best initial industry application for its technology. The SIEV team participated in the University of Arkansas I-Corps site, designed to accelerate the commercialization of research by faculty and students.

“Once we narrowed down our focus, we conducted additional customer discovery interviews with industry leaders, engineers, and researchers from institutions such as the National Renewable Energy Laboratory and began collaborating with one of the largest ethanol producers in the country. We also requested the help of the ASBTDC to gather crucial market research materials and data. Through these conversations and information, we were able to learn more about our customer’s needs,” said Sasongko.

The corn ethanol industry has more than 200 production facilities in the U.S. Being able to produce additional ethanol from cellulosic corn fiber, normally a waste product, will allow ethanol manufacturers to increase profit margins, maximize production efficiencies, and generate additional revenue.

The few commercial technologies currently available to convert corn fiber to useable material are either very expensive, inefficient, or have environmental drawbacks.

“Alternative chemical conversion processes involve the use of toxic and expensive metals that produce hazardous waste,” said Sasongko. “SIEV’s solution is comparatively inexpensive, non-toxic, and robust. This will translate to high yields with lower operating costs and allow ethanol producers to produce cellulosic ethanol profitably.”

Low-Value Biomass Becomes Sustainable Bio-Based Products

During the Phase I project, SIEV wants to optimize the reactor system to process corn fiber and convert it to fermentable sugars with at least 90% yield. The company is also developing a membrane process to separate the sugars from the unreacted material and is designing a lab-scale reactor for fabrication and testing.

The SIEV team has more than 50 collective years of research and development experience working with novel technologies in the areas of membrane separation, catalysis, and biomass conversion. That experience, coupled with their relationship with major industry players and potential customers, positions them for successful commercialization.

“SIEV’s catalyst technology is reusable, green, and environmentally friendly with many potential commercial applications,” Sasongko said.

Although the ethanol industry presents the clearest initial path to commercialization, SIEV has bigger plans.

“Our long-term goal is to create sustainable bio-based chemicals from biomass waste. This will eventually replace many petroleum-based chemicals in the manufacturing of products such as plastics, solvents, adhesives, paints, and much more,” he said.